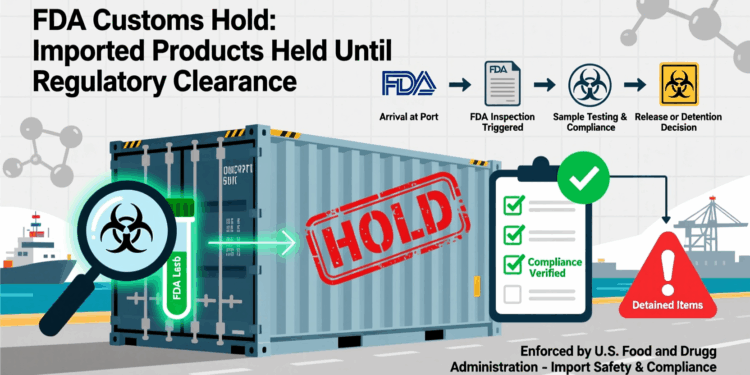

An FDA Customs Hold represents an initial examination phase for imported goods, initiated by the U.S. Food and Drug Administration.

Its core purpose is to ascertain compliance with governing U.S. laws and regulations for food, drugs, cosmetics, and medical devices.

The FDA employs its risk-based screening program, PREDICT, to identify shipments warranting scrutiny. This provisional pause allows for comprehensive assessment prior to release.

The Role of PREDICT in Risk-Based Screening

The Food and Drug Administration (FDA) fundamentally relies upon its sophisticated, automated screening system, the Predictive Risk-based Evaluation for Dynamic Import Compliance Targeting (PREDICT), as the primary and pivotal mechanism for its import examination paradigm. This advanced technological instrument is meticulously designed to implement a highly targeted, risk-based methodology for evaluating the immense volume of products entering the United States.

PREDICT’s core operational objective is the astute analysis of a comprehensive array of data elements pertaining to imported articles, with the overarching aim of identifying potential non-compliance instances well in advance of their physical market entry.

Scope of FDA Import Examination and Regulated Products

The U.S. Food and Drug Administration’s import examination authority is comprehensive, extending across a broad spectrum of products entering the domestic marketplace. This expansive regulatory purview is critical for upholding public health and consumer safety. Specifically, the FDA is empowered to examine any shipment containing regulated articles, which primarily encompass:

- Food and Dietary Supplements: Including raw agricultural commodities, processed foods, beverages, and nutritional supplements, ensuring they are safe, wholesome, and free from adulteration or misbranding.

- Drugs (Pharmaceuticals): Both active pharmaceutical ingredients (APIs) and finished drug products, whether prescription or over-the-counter. Compliance with stringent manufacturing quality, safety, and efficacy standards, as well as proper labeling, is paramount. Recent GLP-1 drug ingredient actions exemplify this robust oversight.

- Medical Devices: A vast category ranging from diagnostic equipment and surgical instruments to implantable devices and in-vitro diagnostics. These products undergo rigorous scrutiny for safety, effectiveness, and adherence to Good Manufacturing Practices (GMP).

- Cosmetics: Products intended for topical application to cleanse, beautify, promote attractiveness, or alter appearance, with a focus on ingredient safety and proper labeling.

- Tobacco Products: Subject to specific regulatory controls concerning manufacturing, labeling, and marketing.

- Radiation-Emitting Electronic Products: Scrutinized for compliance with safety performance standards to mitigate radiation exposure risks.

The scope of FDA’s import examination transcends mere product identification; it delves into various critical aspects of compliance. Examiners assess product composition, ingredient safety, labeling accuracy—verifying adherence to specific format and content requirements—and the overall integrity of the imported article. Furthermore, a critical component involves evaluating the foreign manufacturing facility’s adherence to applicable U.S. standards, including registration requirements and Current Good Manufacturing Practices (CGMP) for drugs and devices.

The FDA’s risk-based screening program, PREDICT, plays a crucial role in directing these examinations by identifying shipments most likely to present compliance concerns. This targeted approach ensures that resources are efficiently deployed to scrutinize imports that may pose the highest potential risk to public health. Importers are therefore unequivocally obligated to maintain accurate and complete documentation, ensure facility registration where required, and certify compliant product labeling as fundamental prerequisites for successful customs clearance and to avert enforcement actions like detention, or refusal.

FDA Hold vs. Detention: Key Differences

An FDA Hold involves a preliminary examination of imports for compliance, often based on PREDICT’s risk screening. Conversely, an FDA Detention is a formal enforcement action, triggered by apparent regulatory violations. A Notice of Detention and Hearing is issued, mandating importer testimony within 10-20 days to avoid refusal. Detention signals a more severe compliance issue.

Issuance of the Notice of Detention and Hearing

When imported articles unequivocally exhibit an apparent violation of the provisions of the Federal Food, Drug, and Cosmetic Act, the U.S. Food and Drug Administration (FDA) formally issues a Notice of Detention and Hearing. This critical document signifies a direct escalation from an initial customs hold, serving as an official, legally binding notification delivered to the importer, owner, or consignee.

It explicitly details that specific products within a shipment have been formally detained. Its issuance denotes a conclusive regulatory finding of apparent non-compliance, moving beyond a mere preliminary inquiry. This pivotal administrative and legal instrument initiates a formal process, demanding a prompt, strategic, and prepared response from the affected party.

The notice thoroughly outlines the precise statutory or regulatory infractions that form the basis for the detention. It further stipulates a crucial “respond by” date, establishing a stringent deadline for submitting compelling “testimony.” This essential testimony, comprising robust evidence and comprehensive arguments, offers the importer the sole opportunity to contest the FDA’s findings, prove product compliance, or propose a viable reconditioning plan designed to meet all applicable U.S. regulatory standards. While the FDA’s authoritative Regulatory Procedures Manual (RPM) typically specifies ten (10) business days for such a response, actual notices frequently specify twenty (20) calendar days, thoughtfully accounting for administrative considerations, including weekends and transit times. This provides a slightly broader, yet still demanding, and ultimately crucial window for thorough preparation.

Absolute adherence to this established timeline is critically imperative to prevent the imposition of significantly more severe enforcement actions, which may include the outright refusal of entry, the mandatory destruction of goods at the importer’s expense, or the assessment of substantial financial penalties. These repercussions can irrevocably impact commercial operations and damage an entity’s reputation. Hence, meticulous attention to detail and exceptionally timely action are paramount to mitigating adverse outcomes, thereby ensuring the most favorable resolution possible for the detained merchandise.

Understanding Testimony Requirements and Response Timelines

Upon receiving an FDA Notice of Detention, importers must submit “testimony”—a formal, evidence-based response addressing the agency’s findings of non-compliance. This critical opportunity allows presenting compelling arguments or proposed corrective actions to overcome the apparent violation, thereby preventing refusal of entry. Testimony requires meticulous fact presentation, refuting or mitigating FDA concerns; content must precisely address specific issues identified. If reconditioning is necessary, a formal request detailing precise actions must be submitted via Form FDA 766, requiring explicit FDA approval. Such submissions demonstrate commitment to regulatory adherence through comprehensive documentation of manufacturing or product specifications.

Strict adherence to prescribed response timelines is paramount. The FDA’s Regulatory Procedures Manual (RPM) typically allows ten (10) business days for testimony submission post-detention. However, official notices frequently specify twenty (20) calendar days; this extended period accounts for weekends and postal transit. Importers must rigorously observe the “respond-by” date on their specific notice. Failure to submit adequate, timely testimony results in administrative refusal, necessitating exportation or destruction. Prompt, thorough response avoids significant financial and logistical repercussions for the importing entity.

The Import Trade Auxiliary Communication System (ITACS) serves as an essential platform for managing this process. It enables importers to efficiently monitor status, securely upload all testimonial documents and evidence, and track estimated laboratory completion dates. Utilizing ITACS streamlines communication, enhances transparency, and facilitates prompt resolution of detention issues. This increases the likelihood of product release with minimal delay. Timely and comprehensive ITACS submission is crucial for a favorable outcome, ensuring compliance and expedited clearance. Proactive utilization is highly advised.

Why is the FDA Holding My Shipment? Common Reasons

Shipments may encounter FDA holds due to a diverse array of regulatory non-compliance issues. Frequent causes include incomplete or inaccurate documentation, non-registration of foreign facilities, and discrepancies in product labeling. Further common reasons involve concerns regarding manufacturing and sanitation practices, the presence of forbidden or restricted substances, and the importation of unapproved drugs. Active import alerts also significantly escalate the likelihood of such interventions.

Importance of Comprehensive Documentation and Facility Registration

Proactive comprehensive documentation and diligent facility registration are foundational to mitigating the risk of U.S. Food and Drug Administration (FDA) import holds. Importers must furnish accurate, complete, and accessible information to regulatory authorities, fundamentally underpinning product compliance assessment, expediting customs clearance.

Robust documentation necessitates critical records: precise product specifications, exhaustive ingredient lists, detailed manufacturing processes, verifiable certificates of analysis, unambiguous country of origin declarations, and all requisite permits. Precision and completeness empower the FDA to conduct efficient evaluations, confirming imported articles conform to U.S. regulatory standards without protracted physical examinations or extensive review cycles. Assigning a U.S. Import Agent further streamlines communication and facilitates timely responses, demonstrating proactive engagement.

Equally paramount is mandatory foreign facility registration, especially for food, pharmaceuticals, and medical devices. The FDA mandates all foreign establishments manufacturing, processing, packing, or holding certain regulated products for U.S. distribution must be officially registered. Absence precipitates immediate import scrutiny, signifying fundamental deviation from established regulatory prerequisites. Mandatory registration endows the FDA with indispensable oversight, enabling effective product tracking, facilitating inspections, and empowering enforcement actions, ensuring consumer safety.

These two integral elements—accurate, complete documentation and proper registration of applicable foreign facilities—are indispensable, upfront methodologies.

They unequivocally demonstrate an importer’s steadfast commitment to regulatory adherence. Meticulously establishing these foundational prerequisites enhances supply chain predictability and reliability, critically diminishing the arduous, financially burdensome likelihood of extensive delays and potential refusals from FDA holds or detentions. Such measures serve as irrefutable, tangible evidence of fidelity to regulatory frameworks, cultivating trust and optimizing efficiency within the complex international import ecosystem. Prioritizing these pivotal aspects transcends mere procedural compliance, establishing itself as a strategic imperative for enduring success in global commerce and safeguarding public health.

Labeling Issues: A Primary Cause for FDA Holds

Non-compliant labeling is a primary cause for U.S. Food and Drug Administration (FDA) customs holds. The FDA enforces comprehensive regulations across all imported food, dietary supplements, cosmetics, and medical devices. Adherence ensures optimal safety and prevents misbranding.

Essential labeling components include:

- Product ID: Clear name.

- Net Quantity: Accurate declaration.

- Responsible Party: Manufacturer/distributor.

- Ingredient List: For foods/cosmetics, by weight; allergen declarations.

- Nutrition Facts Panel: Standardized data for most foods.

Key non-compliance issues triggering FDA holds:

- Misleading/unsubstantiated claims (e.g., unverified health).

- Inaccurate/incomplete ingredient lists (e.g., allergen omission).

- Missing/improper Nutrition Facts.

- Non-English dominant information.

- Absence of critical warnings/directions.

Proactive pre-shipment labeling verification is crucial. This mitigates holds, ensures smooth clearance, and confirms robust compliance.

Manufacturing and Sanitation Concerns: Ensuring Product Safety

Adherence to Good Manufacturing Practices (GMP) is critical, encompassing stringent quality systems and process controls. Failure to comply, including inadequate facility registration for foreign entities, often triggers holds. Comprehensive documentation, demonstrating robust quality assurance and facility hygiene, is essential. This proactive measure prevents administrative detention stemming from non-compliance, ensuring public health safeguards.

Administrative Detention for Food Product Non-Compliance

Administrative detention is a stringent enforcement action specific to food products, employed by the U.S. Food and Drug Administration (FDA). Its core purpose is to prevent the distribution of food items appearing adulterated or misbranded, thereby violating federal food safety laws or posing a public health risk. This authority enables the FDA to detain goods decisively upon credible evidence of non-compliance, ensuring public safety and maintaining market integrity.

This action differs from standard customs holds, being invoked when serious concerns arise regarding a food product’s safety or manufacturing integrity, such as health hazards or insanitary production conditions. The swift detention aims to proactively remove harmful food from the commercial supply chain. Importers receive formal notification detailing the reasons for detention and available recourse options.

The importer bears the responsibility to demonstrate compliance. This necessitates compelling evidence that the food product, or its production environment, fully adheres to the Federal Food, Drug, and Cosmetic Act. Guidance is found in FDA resources like the “What You Need to Know About Administrative Detention of Foods; Small Entity Compliance Guide,” meticulously outlining agency policy. Prompt, thorough responses, including laboratory analyses, robust facility records, and corrective action plans, are essential. Insufficient testimony can result in refusal of entry, product destruction, or severe regulatory penalties. This critical tool underscores the FDA’s commitment to safeguarding the nation’s food supply by maintaining rigorous safety and quality standards.

Forbidden or Restricted Substances & FDA Import Alerts

The U.S. Food and Drug Administration (FDA) restricts or prohibits the import of unapproved, adulterated, or misbranded substances. The primary enforcement tool for this is the Import Alert system.

Key Concepts:

-

Import Alert: A publicly available notice that identifies products and/or manufacturers with a history of violations.

-

Detention Without Physical Examination (DWPE): Products on an Import Alert’s “Red List” can be detained at the border without being physically examined because they appear to violate FDA laws.

-

Red List: The list of specific products, manufacturers, or shippers that are subject to DWPE under a given Import Alert.

-

Green List: In some alerts, a list of firms or products that are exempt from DWPE because they have demonstrated compliance.

A Current and Specific Example: GLP-1 Drug Ingredients

A prominent recent example involves Active Pharmaceutical Ingredients (APIs) for Glucagon-like Peptide-1 (GLP-1) receptor agonists (e.g., semaglutide, tirzepatide).

-

The Problem: The FDA has encountered unapproved and compounded versions of these popular diabetes and weight-loss drugs, some of which use non-compliant salt forms of the API.

-

The Action: The FDA issued Import Alert 66-78 and related alerts to detain these unapproved APIs.

-

The “Green List” Solution: To mitigate drug shortages while ensuring safety, the FDA created a “Green List” for GLP-1 APIs under Import Alert 66-80. Only APIs from manufacturers on this vetted list are allowed entry. All others are subject to immediate DWPE.

Consequences of Discovery:

If a shipment containing a forbidden or restricted substance (like an unapproved GLP-1 API) is discovered, the FDA will:

-

Immediately Detain the shipment.

-

Refuse its entry into the United States.

-

Potentially place the manufacturer/shipper on a “Red List,” making all their future shipments subject to automatic detention.

How to Find the Current Lists

There is no single, static “Red List” of all forbidden substances. The information is dynamic and spread across hundreds of individual Import Alerts. To find the current status:

-

Search the FDA Import Alert Database: This is the official, real-time source.

-

Use Keywords: Search for a specific substance (e.g.,

"semaglutide"), a manufacturer’s name, or a product type. -

Browse by Category: You can browse alerts by industry (e.g., Drugs, Food, Medical Devices) or by country of origin.

Proactive vetting of suppliers and strict adherence to FDA regulations are essential to avoid these severe enforcement actions.

Consequences and Specifics of FDA Import Alerts

FDA Import Alerts constitute a stringent enforcement mechanism, rigorously preventing non-compliant articles from entering the U.S. market. An alert signifies the Food and Drug Administration’s determination that a specific product, manufacturer, or goods from an entire country, pose a demonstrable risk of violating U.S. laws and regulations. The paramount consequence for entities operating under an import alert is the automatic detention of their future shipments without physical examination. This proactive regulatory measure decisively shifts the burden onto the importer to affirmatively demonstrate full compliance. Such alerts empower the FDA to enhance its control over product categories or firms exhibiting persistent regulatory shortcomings, thereby ensuring public health and maintaining supply chain integrity.

A salient example of such specific enforcement is the agency’s recent tightening oversight on glucagon-like peptide-1 (GLP-1) active pharmaceutical ingredient (API) imports. In this instance, a specific import alert was judiciously issued alongside a “green list” for manufacturers demonstrating compliance. This action underscores the FDA’s focused enforcement on critical ingredients, directly addressing safety concerns and safeguarding public health. Once an article falls under an alert’s purview, all subsequent entries face automatic detention, necessitating comprehensive evidence of sustained adherence to U.S. requirements for any release. Overcoming an import alert mandates a verifiable, comprehensive approach. Importers must present robust testimony detailing sustained corrective actions, meticulously demonstrating fundamental changes in manufacturing processes, quality controls, and documentation protocols. This process aims to conclusively prove to the FDA that future shipments consistently meet all prescribed regulatory standards. Ultimately, these stringent alerts are indispensable tools for upholding product safety and consumer confidence within regulated sectors.

Unapproved Drugs: Understanding the Approval Process

Importing unapproved drugs into the U.S. necessitates a rigorous understanding of FDA’s stringent approval process. All pharmaceutical products, whether brand-name or generic, must undergo FDA evaluation. The agency is tightening oversight, evidenced by recent import alerts on GLP-1 drug ingredients, underscoring severe consequences for non-compliance. Verification of approval is paramount to avoid detentions.

Strategies for Releasing Detained Goods and Reconditioning Options

Upon receiving a Notice of Detention, importers are presented with a critical window to implement strategies for the release of their goods. The initial and most crucial step involves submitting comprehensive testimony to the FDA. This testimony, which serves as the importer’s formal response, must meticulously address the deficiencies cited in the detention notice and provide compelling evidence to demonstrate compliance or a viable path to achieving it. The FDA’s Regulatory Procedures Manual (RPM) typically allows ten business days for testimony, though notices often extend this to twenty calendar days to allow for thorough preparation and accommodate non-working days. Leveraging systems like the Import Trade Auxiliary Communication System (ITACS) is crucial for status checks, document uploads, and monitoring laboratory completion dates, thus streamlining communication.

Proactive compliance is critical in mitigating detention risks. Maintaining accurate and exhaustive documentation on file with the FDA, encompassing the proper assignment of a U.S. Import Agent, ensuring that foreign facilities are duly registered where applicable, and guaranteeing product labeling compliance, constitutes foundational elements for successful import operations. These measures collectively demonstrate an importer’s unwavering commitment to regulatory adherence and significantly reduce the likelihood of enforcement actions. Should a product be deemed suitable for reconditioning, thereby enabling it to meet FDA standards, the importer must formally request permission.

This is achieved by submitting Form FDA 766, which mandates a detailed description of the precise actions proposed to bring the article into full compliance. This reconditioning plan must be explicit, outlining every step intended to rectify the identified violations. Successful reconditioning, followed by FDA verification, is often the most direct route to overcoming a detention and securing the release of the shipment, thereby avoiding more severe consequences such as refusal of entry or destruction of the goods. The efficacy of these strategies hinges on prompt action, thorough preparation, and an intricate understanding of FDA’s procedural requirements.